Products: Water Pump

Khoory Pressure Boosting and Liquid Transfer

Vertical Booster Pump Set

Horizontal Booster Pump Set

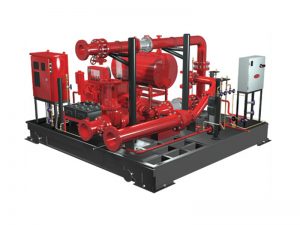

Fire Pump Set

Khoory-Grundfos dubai packaged transfer pump set, booster pump set and fire fighting sets are the ultimate solution for water supply in high-rise buildings & villas, high-pressure water cleaning systems & industrial water supply systems, irrigation systems, land scraping purpose, etc.

They are supplied as a complete system suitable for all requirements. The package system includes up to 2, 4, 6, 8 etc. onwards pumps in parallel subject to the size of the water pressure and flow system requirements (1m3/hr to 2500m3/hr).

The set will be delivered as a complete package unit which consists of pumps, pressure vessel, pressure switch, guages, control panel, valves and fittings, all mounted on a common base frame. Materials for various components can be mild steel, copper, SS of various grades, galvanized, acrylic, painted or any other specified alloy.

Fire Fighting Sets are approved by and meet local civil defense regulations. They can be designed to meet either NFPA or LPC standards.

Deisel engine size, pump capacity, pressure tank and control panel are selected to meet the specific duty conditions.

They can also be designed to match all requirements for either fire hose reel or sprinkler systems.

With over 35 years of extensive experience in the field of pumping systems, M.A.H.Y. Khoory is able to supply a professional and quality solution to match all systems.

Heating and Hot Water Cooling Service Systems

UPS, UP Series 100

Applications: Circulation of hot or cold water in- Heating systems

– Domestic hot water systems

– Cooling and air-conditioning systems.

Options

– Automatic performance adjustment

– Display of actual power consumption

– Automatic night-time duty

– Simple installation – external plug for electrical connection

– Single-speed or 2- or 3-speed performance adjustment

– Twin-head versions

NB, NBG

Features and Benefits- Standard dimensions according to EN and ISO standards

– Compact design

– Flexible pump range

– Standard motor

– Adaptable to any application and performance

– EN 12 756 shaft seal

Technical Data

– Flow, Q: Max.460 m3/h

– Head, H: Max. 95 m

– Liquid temp.: – 25°C to +140°C

– Operat. pres.: Max. 16 bar

Applications: The pumps are suitable for liquid transfer in

– District heating plants

– Heating systems for blocks of flats

– Air-conditioning systems

– Cooling systems

– Washdown systems

– Other industrial systems

Options

– Various types of shaft seal depending on liquid, temperature and pressure

– Cast iron or bronze impeller

NBE

Features and Benefits- Standard dimensions according to EN standards

– Compact design

– Adaptable to any application and performance

– EN 12 756 shaft seal

– Many control facilities

Technical Data

– Flow, Q: Max.460 m3/h

– Head, H: Max. 95 m

– Liquid temp.: – 25°C to +140°C

– Operat. pres.: Max. 16 bar

Applications: The pumps are suitable for liquid transfer in

– Washing systems

– Water supply systems

– District heating plants

– Cooling and air-conditioning systems

– Industrial plants

Options

– Various types of shaft seal depending on liquid, temperature and pressure

– Cast iron or bronze impeller

– Wireless remote control, R100

NK, NKG

Features and Benefits- Standard dimensions according to EN standards

– Wide range

– Robust design

– Heavy-duty

– Flexible motor range

Technical Data

– Flow, Q: Max.2000 m3/h

– Head, H: Max. 150 m

– Liquid temp.: – 25°C to +140°C

– Operat. pres.: Max. 16 bar

Applications: The pumps are suitable for liquid transfer in

– District heating plants

– Water supply systems

– Air-conditioning systems

– Cooling plants

– Industry

– Fire fighting systems

– Environment engineering

Options

– Various types of shaft seal depending on liquid, temperature and pressure

– Cast iron or bronze impeller

TP

Features and Benefits

– Standard dimensions according to EN standards

– Wide range

– Standard motor

– Service-friendly

– Various types of shaft seals depending on liquid, temperature and pressure

Technical Data

– Flow, Q: Max.4600 m3/h

– Head, H: Max. 170 m

– Liquid temp.: – 25°C to +150°C

– Operat. pres.: Max. 25 bar

Applications: Circulation of hot or cold water in

– Heating systems

– District heating plants

– Local heating plants

– Domestic hot water systems

– Cooling and air-conditioning systems

Options

– Bronze pump housing

– Twin-head versions

TPE Series 2000

Features and Benefits

– Low-energy

– Adaptation to existing operating conditions

– Simple installation

Technical Data

– Flow, Q: Max. 370 m3/h

– Head, H: Max. 90 m

– Liquid temp.: – 25°C to +140°C

– Operat. pres.: Max. 16 bar

Applications: Circulation of hot or cold water in

– Heating systems

– Domestic hot water systems

– Cooling and air-conditioning systems

Options

– Parallel operation

– Wireless remote control, R100

– Communication via GENIbus or LON

– Twin-head versions

UPS Series 200

Features and Benefits

– Low-energy

– Adaptation to existing operating conditions

– Simple installation

Technical Data

– Flow, Q: Max. 370 m3/h

– Head, H: Max. 90 m

– Liquid temp.: – 25°C to +140°C

– Operat. pres.: Max. 16 bar

Applications: Circulation of hot or cold water in

– Heating systems

– Domestic hot water systems

– Cooling and air-conditioning systems

Options

– Parallel operation

– Wireless remote control, R100

– Communication via GENIbus or LON

– Twin-head versions

Cooling and Air-conditioning Systems

CH, CHN

CHV

CR, CRI, CRN

UPS, UP Series 100

TPE Series 1000

NB, NBG

NBE

NK, NKG

TP

Features and Benefits- Low-energy

– Adaptation to existing operating conditions

– Simple installation

– Many control facilities

– Wireless remote control, R100

– Communication via GENIbus or LON

Technical Data- Flow, Q: Max. 370 m3/h

– Head, H: Max. 90 m

– Liquid temp.: – 25°C to +140°C

– Operat. pres.: Max. 16 bar

ApplicationsThe pumps are suitable for liquid transfer in- District heating plants

– Cooling and air-conditioning systems

– Industrial plants.

Industrial Applications

CH, CHN

CR, CRI, CRN

DME, DMS

Features and Benefits

– Precise capacity setting in ml or l

– Full diaphragm control

– Stroke speed or stroke frequency capacity control

– Operation panel with display and onetouch buttons

– Front- or side-fitted operation panel

– Manual/pulse control

– Control panel lock

– 4-20 mA control

– Pulse-/timer-based batch control

– Anti-cavitation function

– Easy calibration function

– Fieldbus communication module (option)

– Leakage sensor

Technical Data

– Capacity, Q: Max. 150 l/h

– Pressure, p: Max. 18 bar

– Liquid temp.: Max +50°C

Applications

Injection of chemicals in water and waste

water treatment systems, washing systems,

swimming-pools and process

plants.

Domestic Water Supply

CH, CHN

CHV

CR, CRI, CRN

DME, DMS

Features and Benefits

– Precise capacity setting in ml or l

– Full diaphragm control

– Stroke speed or stroke frequency capacity control

– Operation panel with display and onetouch buttons

– Front- or side-fitted operation panel

– Manual/pulse control

– Control panel lock

– 4-20 mA control

– Pulse-/timer-based batch control

– Anti-cavitation function

– Easy calibration function

– Fieldbus communication module (option)

– Leakage sensor

Technical Data

– Capacity, Q: Max. 150 l/h

– Pressure, p: Max. 18 bar

– Liquid temp.: Max +50°C

Applications

Injection of chemicals in water and waste

water treatment systems, washing systems,

swimming-pools and process

plants.

Wastewater

DP, EF, SE1 and SEV

Unilift CC, KP, AP12, AP35/50, AP35B/50B

SEG

SE

Features and Benefits

– Cable plug connection

– Unique clamp connection

– Single-channel and vortex impellers

– Solids passage up to 65 mm

– Unique cartridge shaft seal

– Modular design

– Minimum downtime

Technical Data

– Flow, Q: Max. 19,5 m3/h (70 m3/h)

– Head, H: Max. 25 m

– Liquid temp.: 0°C to +40°C

– Disc. diameter: Rp 2 to DN 65

Applications

The pumps are suitable for:

– Drainage

– Effluent

– Wastewater

– Process water

– Domestic sewage

Options

– Control and protection systems

– Motor operation control

Dosing

DME, DMS

Features and Benefits

– Precise capacity setting in ml or l

– Full diaphragm control

– Stroke speed or stroke frequency capacity control

– Operation panel with display and onetouch buttons

– Front- or side-fitted operation panel

– Manual/pulse control

– Control panel lock

– 4-20 mA control

– Pulse-/timer-based batch control

– Anti-cavitation function

– Easy calibration function

– Fieldbus communication module (option)

– Leakage sensor

Technical Data

– Capacity, Q: Max. 150 l/h

– Pressure, p: Max. 18 bar

– Liquid temp.: Max +50°C

Applications

Injection of chemicals in water and waste

water treatment systems, washing systems,

swimming-pools and process

plants.

Submersible Pumps, Motors and Controls

SP A, SP, SP-G

MS MOTORS

MMS MOTORS

Features and Benefits

– High efficiency

– Long service life as all components are stainless steel

– Motor protection via CU 3

Technical Data

– Flow, Q: Max. 470 m3/h

– Head, H: Max. 670 m

– Liquid temp.: 0°C to +60°C

– Intal. depth.: Max. 600 bar

Applications

The pumps are suitable for

– Groundwater supply to waterworks

– Irrigation in horticulture and agriculture

– Groundwater lowering

– Pressure boosting

– Industrial applications

Options

Data can be monitored and controlled via MP 204